Custom merchandise is a powerful branding tool, whether for businesses, events, or personal use. It transforms everyday items into walking advertisements, memorable keepsakes, and unified team apparel. Two of the most popular printing methods are vinyl plotting and heat press printing, each offering distinct advantages depending on design complexity, durability, and material compatibility. Understanding these differences is crucial for achieving the desired look and longevity of your custom merch.

For customers looking to order custom merch from a professional printing company, understanding these methods can help ensure you choose the right option for your needs. This comprehensive guide will break down the key differences, helping you determine the best method based on factors like design style, durability, and cost-effectiveness. By exploring the nuances of each technique, you'll be equipped to make informed decisions that align with your specific project requirements.

What is Vinyl Plotting?

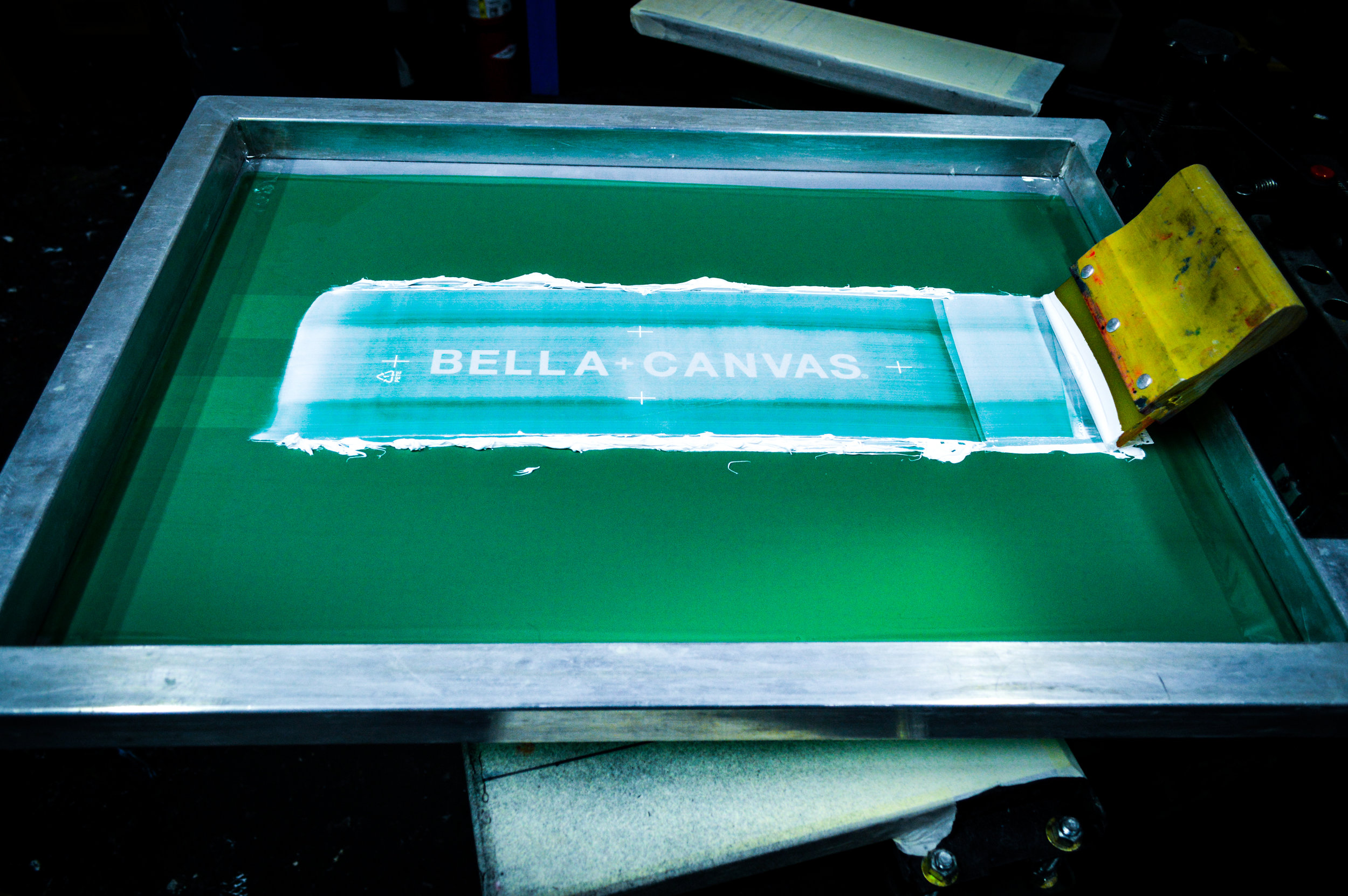

Vinyl plotting is a precise cutting technique that utilizes a computer-controlled vinyl cutter or plotter. This machine cuts out designs from thin sheets of adhesive or heat transfer vinyl (HTV). The excess vinyl is then "weeded" away, leaving only the desired design. This cut-out design is subsequently heat-pressed onto fabric or other surfaces using a specialized heat press machine, which applies heat and pressure to bond the vinyl to the material.

The Process in Detail:

The design is created using vector graphics software.

The vinyl cutter, guided by the software, precisely cuts the design into the vinyl sheet.

The excess vinyl is removed (weeding).

The design is positioned on the fabric.

Heat and pressure are applied to adhere the vinyl.

Why Choose Vinyl Plotting for Your Custom Merch?

Best for simple, bold designs with 1-2 colors: Vinyl plotting excels at creating clean, sharp lines and solid shapes. It’s ideal for designs that don’t require intricate color blending or gradients.

Works well for logos, team names, and sports jerseys: The durability and crispness of vinyl plotting make it a popular choice for sports apparel, where names, numbers, and team logos need to withstand frequent washing and wear.

Provides a slightly raised, textured feel: The vinyl layer adds a tactile dimension to the fabric, giving it a premium, high-quality feel. This raised effect can enhance the visual appeal of the design.

Extremely durable, lasting through multiple washes: High-quality vinyl is designed to be resilient, resisting cracking, peeling, and fading even after numerous wash cycles. This makes it a reliable option for items that require frequent laundering.

What is Heat Press Printing?

Heat press printing is a broader term encompassing various techniques that use heat and pressure to transfer designs onto fabric or other surfaces. This method includes sublimation, DTF (direct-to-film), and screen-printed transfers, each with its unique characteristics and applications.

Sublimation: Dyes are infused directly into the fabric at a molecular level, resulting in a vibrant, long-lasting print.

DTF: A design is printed onto a special film, which is then heat-pressed onto the fabric. This method is known for its versatility and ability to produce detailed, full-color prints.

Screen-printed transfers: Ink is applied to a transfer paper, which is then heat-pressed onto the fabric. This method is ideal for bulk orders and designs with a limited number of colors.

Why Choose Heat Press Printing for Your Custom Merch?

Ideal for full-color and intricate designs: Heat press methods like sublimation and DTF can reproduce complex designs, photographs, and gradients with exceptional clarity and detail.

Great for branded apparel, event shirts, and promotional items: The ability to print vibrant, detailed designs makes heat press printing suitable for creating eye-catching promotional merchandise and event apparel.

Works on a variety of surfaces, including polyester and synthetic fabrics: Heat press techniques are versatile and can be used on various materials, including polyester, synthetic blends, and even non-fabric items like mugs and tote bags.

Offers a soft, seamless finish: Sublimation, in particular, results in a print that is integrated into the fabric, providing a smooth, comfortable feel without any raised texture.

Materials & Fabric Compatibility

The choice of printing method is significantly influenced by the fabric type. Different materials react differently to heat and pressure, affecting the print quality and durability.

Vinyl Plotting:

Best for cotton, polyester, and nylon: Vinyl adheres well to these fabrics, providing a strong and durable bond.

Not suitable for fabrics that cannot withstand high heat.

Heat Press Printing:

Works well on polyester, synthetic blends, and even non-fabric materials like mugs or tote bags: Sublimation, in particular, requires polyester or polymer-coated materials.

For 100% polyester fabrics, sublimation (a heat press method) is the best option: Sublimation dyes bond permanently with polyester fibers, resulting in vibrant, fade-resistant prints.

Cotton garments often work better with vinyl or DTF heat transfers: While sublimation is not ideal for cotton, DTF and vinyl offer excellent adhesion and durability.

Durability & Washability

Customers expect their custom merch to withstand regular use and washing without losing its visual appeal.

Vinyl Plotting:

Resistant to peeling and cracking: High-quality vinyl is designed to withstand repeated washing and wear.

Holds up well for sports jerseys and workwear: Its durability makes it suitable for items that require frequent laundering.

Can last 50+ washes with proper care: Following care instructions, such as washing in cold water and avoiding harsh detergents, can extend the lifespan of vinyl-printed items.

Heat Press Printing:

Sublimation prints never crack or peel (they fuse into the fabric): The dyes become part of the fabric, ensuring a long-lasting, seamless print.

Screen-printed transfers are durable but may fade over time: While screen-printed transfers are generally durable, they may show signs of wear and tear after many washes.

Requires proper care (gentle washing, no harsh detergents): Similar to vinyl, heat-pressed items benefit from gentle washing and avoiding harsh chemicals.

Design Complexity & Customization

The complexity of your design will significantly influence the choice of printing method.

Vinyl Plotting:

Best for solid-color, bold designs: Vinyl plotting excels at creating clean, sharp lines and solid shapes.

Can be layered for multiple colors but is not ideal for gradients: While layering is possible, it can add thickness and complexity to the design.

Great for names, numbers, and logos: Its precision and durability make it ideal for these types of designs.

Heat Press Printing:

Ideal for detailed, multi-color graphics: Techniques like sublimation and DTF can reproduce intricate designs with exceptional clarity.

Can produce photo-quality and gradient prints: These methods allow for seamless color blending and detailed photographic images.

Works well for large, colorful designs like event shirts: Heat press printing is perfect for creating eye-catching, vibrant designs for large events.

Speed & Turnaround Time

The production speed of each method can impact the turnaround time for your custom merch order.

Vinyl Plotting:

Requires cutting, weeding, and heat pressing for each design: This manual process can be time-consuming, especially for intricate designs.

Best for smaller orders or personalized items: Vinyl plotting is well-suited for small-batch orders and personalized items.

Can take longer if the design is intricate: Complex designs with multiple layers and small details require more time for weeding and application.

Heat Press Printing:

More efficient for bulk orders: Techniques like sublimation and screen-printed transfers allow for faster production of large quantities.

Sublimation and screen-printed transfers allow faster production: These methods can produce multiple items simultaneously, reducing overall production time.

Ideal for large event orders, corporate apparel, and promotional items: Heat press printing is ideal for large-scale projects with tight deadlines.

If you need hundreds of items printed quickly, heat press printing is often the faster option.

Cost-Effectiveness for Custom Merch Orders

The cost of each method varies depending on order size and design complexity.

Vinyl Plotting (Best for Small Orders):

Ideal for one-off prints, team jerseys, or personalized gifts: The manual process makes it cost-effective for small orders.

Less cost-effective for large batches due to manual application: The labor-intensive nature of vinyl plotting increases costs for bulk orders.

Higher pricing per item for multi-color designs: Each color layer adds to the overall cost.

Heat Press Printing (Best for Bulk Orders):

More affordable for large runs (e.g., 50+ shirts): The efficiency of heat press methods reduces costs for bulk orders.

Sublimation and DTF transfers reduce labor costs: These techniques allow for faster production, lowering labor costs.

Ideal for businesses needing large quantities of branded merch: Heat press printing is a cost-effective solution for large-scale promotional campaigns.

A professional printing company can recommend the best method based on your budget, design needs, and order size.

Best Use Cases: When to Choose Vinyl Plotting vs. Heat Press

Each method is better suited for specific types of merchandise.

Vinyl Plotting is Best for:

✔ Custom sports jerseys, team names, and uniforms

✔ Small-batch orders with simple designs

✔ Workwear and promotional apparel that needs extra durability

Heat Press Printing is Best for:

✔ Event merchandise (concerts, fundraisers, business promos)

✔ Photo-quality designs and colorful prints

✔ Large orders where cost and speed matter

Conclusion

Both vinyl plotting and heat press printing are excellent options for custom merchandise, but the best choice depends on design complexity, durability, and order size. If you need simple, highly durable designs, vinyl plotting is a great choice. For full-color, high-volume orders, heat press printing is the better option.

By working with an experienced merch printing company, you can ensure the best quality, durability, and cost-effectiveness for your custom apparel and promotional products. They can guide you through the selection process, helping you choose the method that best aligns with your specific needs and budget.