poster printing dept.

A behind the scenes look at the FAMILY INDUSTRIES poster printing department

We love screen printing posters. The poster printing process has a lot of similarities to printing apparel, but it takes a steadier hand, more attention to detail, and experience to the get final product just right! We always get a ton of questions about how the poster printing process works and why it's different than printing apparel. Our in-house team consists of two master printers, Joe and Able. Combined they have over 40 years of printing experience.

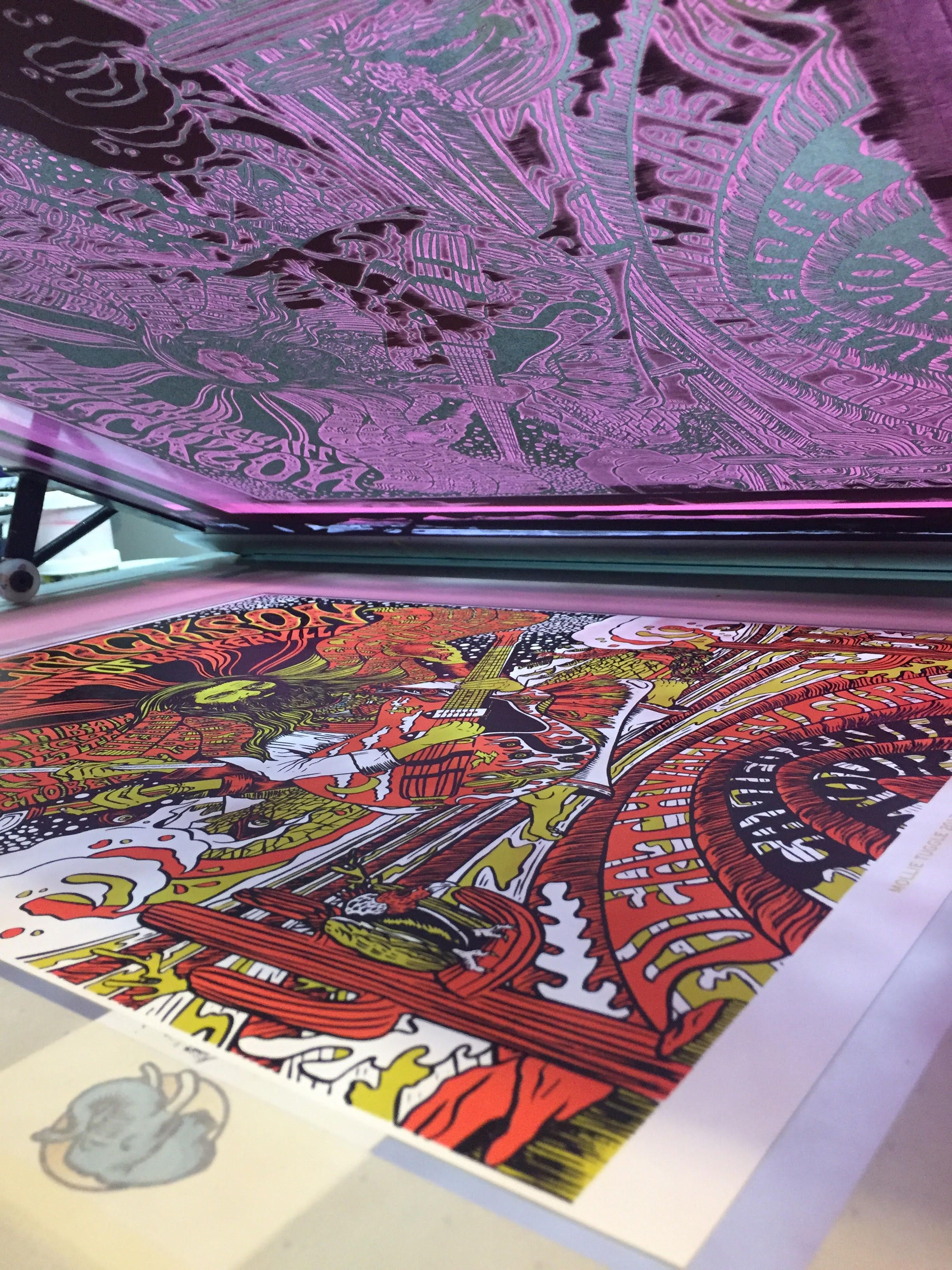

Our poster printing department tends to work with artists who need fine art print runs, and bands who need highly detailed gig posters. This past week, we worked with Mollie Tuggle, an experienced designer and artist who designed an amazing gig poster for the legend, Roky Erickson.

Below we take you through our in-house process of printing a poster from start to finish!

Step 1. check artwork, print films, and mix inks

We first check out the final artwork that is approved & received. It should have layers showing the different colors that will be printed on the blank stock paper. Next, we print films that are used to burn the images into the screens. Screens for poster printing are much larger than used for apparel prints so we can print super-sized designs! Our crew matches the waterbased inks by eye, and we do several swatch tests to ensure a great match.

2. Start printing

Screens are burned, inks are mixed, and we're ready to roll. The decision of which layers to print first is determined by the design. Making sure parts of the artwork called "traps" are in proper placement helps us in working out the best order of colors. Our printing press has a vacuum that keeps the paper in-place during all these changes. If there are multiple layers, we pause after each is completed to let the ink dry before moving to the next one!

3. next round of color

Posters are printed in layers. Each color needs to properly dry before the next color of ink is applied to the paper. Posters are definitely a "craft" process and need careful planning in order to achieve the best possible look.

4. prepare for delivery

After all the printing is wrapped, we let the custom printed posters air dry. Waterbased ink doesn't need to go through a heated dryer, but rather air dries as the moisture dissipates from the stock. After that, it's time to get the prints into a box for pickup or shipping!